Introduction

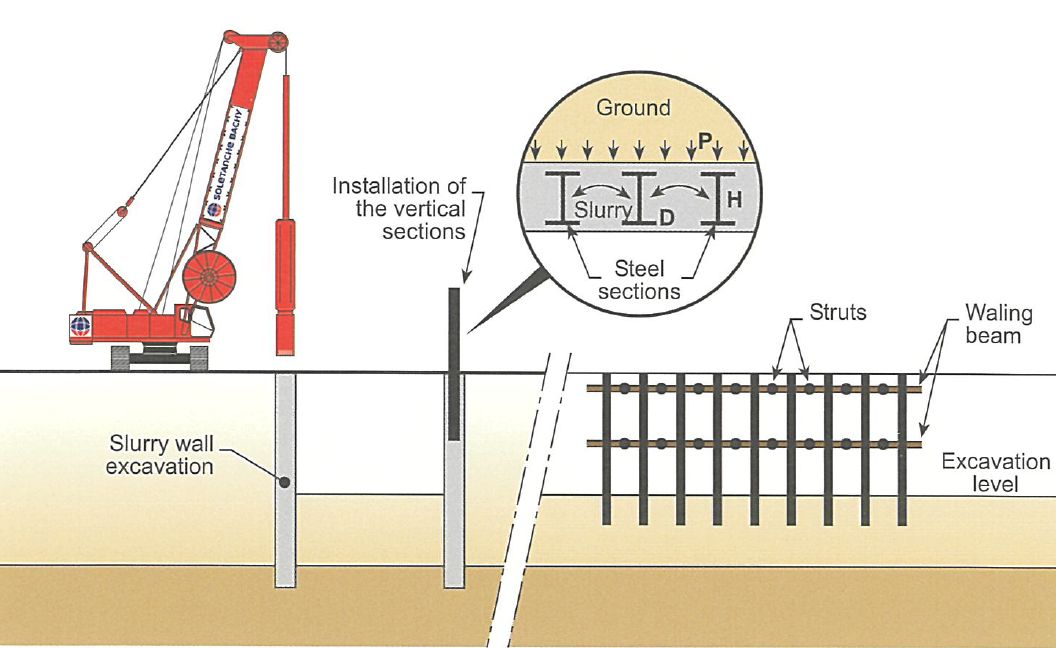

Reinforced slurry walls are derivatives of the diaphragm wall technology and are also commonly used by Bachy Soletanche to construct retaining structures. They have multiple functions that are retaining structures and water cut-off respectively. The wall thickness ranges from 800mm to 1500mm.

Reinforced slurry walls use the same excavation methods as for diaphragm walls. The trench is excavated under bentonite slurry by grab, chisel and/or hydrofraise, then replaced by bentonite-cement slurry with reinforced steel H sections. Shear pins can also be installed within the walls if required. Reinforced slurry walls are constructed panel by panel with overlapping to ensure the water tightness.

General Processes

The general construction sequences of reinforced slurry walls are similar as diaphragm walls as descripted below:

- Construct temporary reinforced guide walls,

- to provide physical confirmation of panel location,

- to guide the excavation tool,

- to maintain the bentonite slurry to required level,

- to support the reinforced steel H sections.

- Excavate the panel to required depth by grab, chisel and/or hydrofraise,

- Desanding / substitution of the bentonite slurry and panel base cleaning,

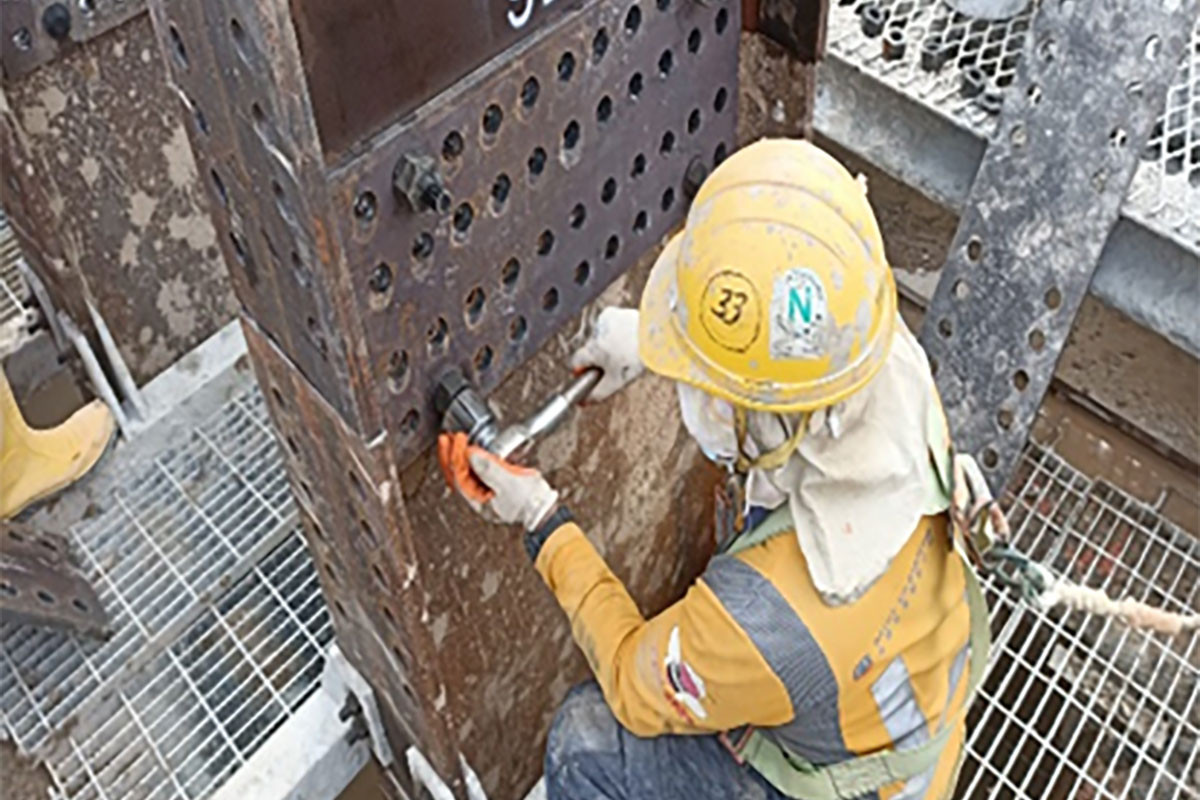

- Installation of reinforced steel H sections,

- Replace the bentonite slurry with bentonite-cement slurry by tremie method.