Introduction

The technique of reinforced soil mixing walls involve in-situ mixing of soil with binding agent such as cement to reinforce the in-situ soil, then incorporating structural reinforcements into the mix to form a retaining structure. Usually the structural reinforcements are steel H sections.

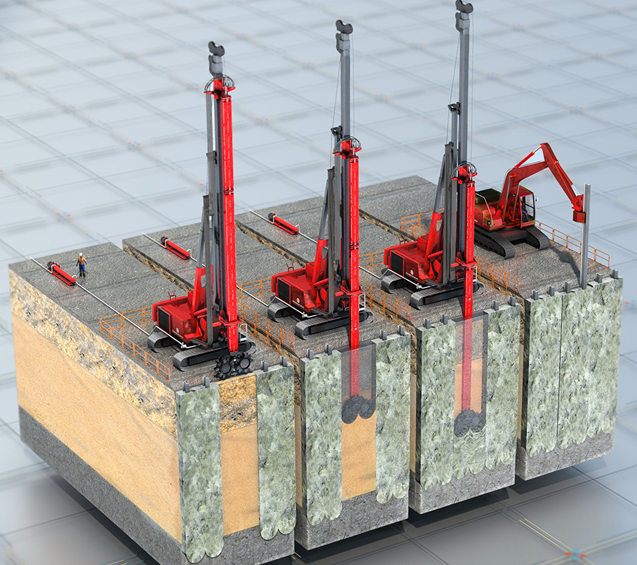

Bachy Soletanche has developed the GEOMIX process for soil mixing using a tailor-made tool named Cutter Soil Mixing (CSM) that combines the Deep Soil Mixing technique with Hydrofraise technology to mix the soil in place mechanically by incorporating cement. This equipment comprises a real time control system to guarantee the homogeneity of the mix and the verticality of the soil-cement mix panel.

CSM consists of hydraulic motors upon which two pairs of rotating drums are mounted. These carry out the excavation and mixing of the in-situ soil with cement grout. This equipment is compatible with numerous types of base units, which makes it very flexible in use.

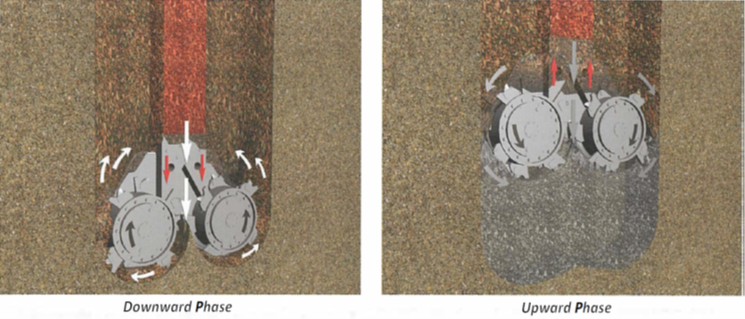

GEOMIX is a 2-phase process. A downward phase is to destruct the soil and an upward phase is to homogenize the mix. The grout binder can be incorporated during either of these two phases. The type and quantity of binder determine the hydraulic and mechanical characteristics of the soil after treatment (mixing).

CSM forms soil-cement mix in a single bite with thickness ranging from 800mm to 1200mm. Continuous walls can be created by a succession of overlapping bites, built following a primary secondary sequence.

Highlights

Bachy Soletanche has successfully implemented the cutter soil mixing technique in land and marine conditions on landmark projects such as the Three Runway System of Hong Kong International Airport. This technique is a highly competitive solution for improving the bearing capacity of alluvial and reclamation soils.