Introduction

Large diameter bored piles are the most traditional and common form of piling worldwide, which are capable of supporting very high loads and coping with complex ground conditions. They are mainly used in the foundations of heavy structures, but may also be used as retaining structure such as secant bored pile walls.

Large diameter bored piles are usually made of reinforced cast-in-situ concrete, in which the reinforcement can also be a steel section to build retaining walls such as soldier pile walls. The pile diameter ranges from 800mm to 3300mm. They can be installed to a depth exceeding 100m, and the pile base can be enlarged (bell-out) to increase their load bearing capacity.

General Processes

Large diameter bored piles are excavated by auger, rock bucket, grab, chisel and/or reverse circulation drill (RCD) rig. A temporary steel casing will be installed into ground to support the unstable strata and ensure safe working conditions on ground / working platform. The casing is installed by the piling rig using oscillator, rotator or vibrator. However, carrier fluids such as bentonite or polymer may be a more effective way of stabilizing a deep pile bore than using a longer casing. The general principle is to maintain a positive hydrostatic fluid load in the bore above groundwater level, same as diaphragm wall technique.

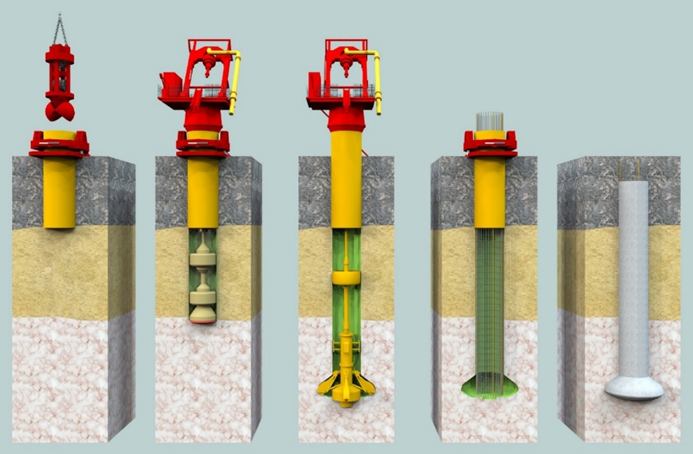

Subsequent to the pile boring, the following processes will be followed.

- Enlarge the pile base (bell-out) by belling tool,

- Air-lifting and pile base cleaning,

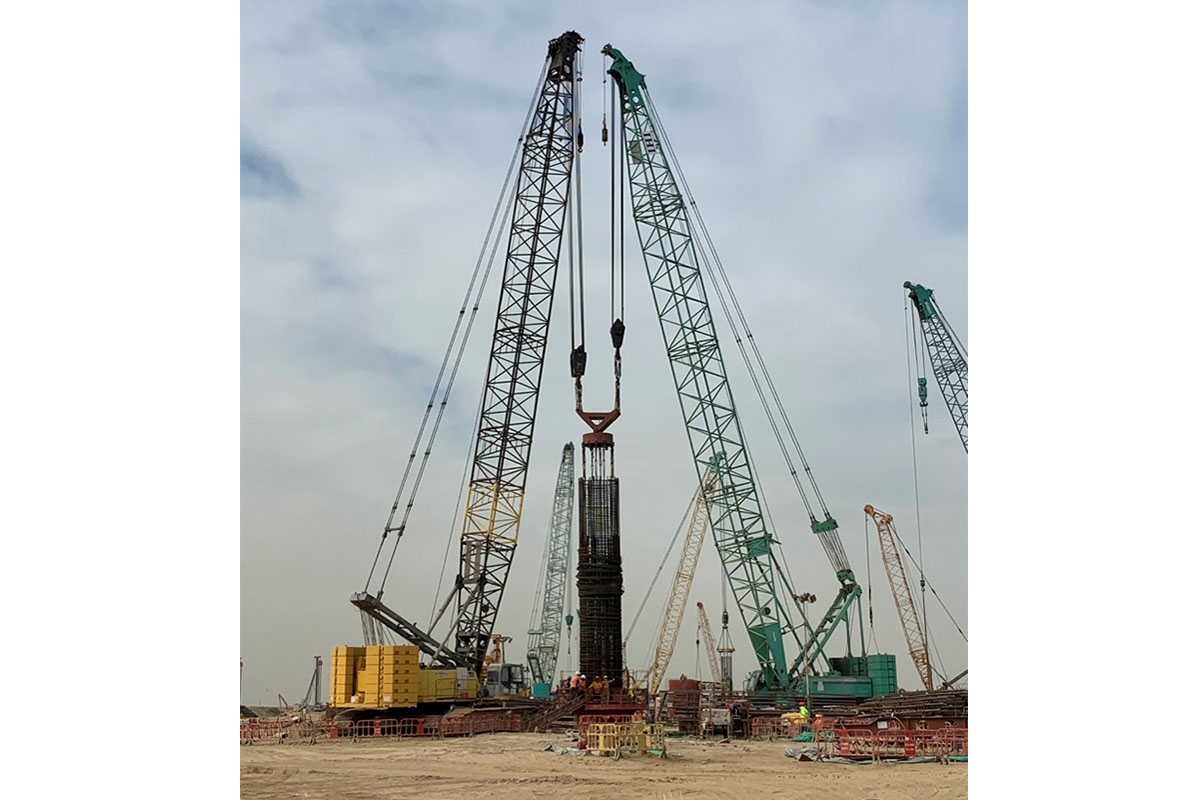

- Installation of steel reinforcement,

- Concreting of the pile by tremie method. During the course, temporary casing will be removed gradually.